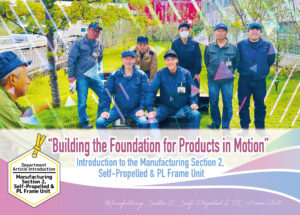

Department Introduction Article –Manufacturing Section 2, Self-Propelled & PL Frame Unit “Building the Foundation for Products in Motion”

Nice to meet you! We are the team at Okudaya Giken responsible for creating the “foundation for products in motion” — the Manufacturing Section 2, PL & Self-Propelled Frame Unit!

At first glance, our work may look like a simple skeleton of steel. However, the precision of this frame alone dictates both the driving performance and the safety of the final product. In a world where even a 1mm deviation is unacceptable, every day is a new challenge and a step forward in our pursuit of perfection.

From here, we would like to introduce the primary responsibilities and daily operations of the PL & Self-Propelled Frame Unit.

●Frame Fabrication and Assembly

Based on the technical drawings, we weld and assemble each part with millimeter-level precision. Even the slightest distortion can impact driving performance and load balance later on, so our true craftsmanship is put to the test as we fabricate the structures while relying on the guidance of senior colleagues and accurate blueprints.

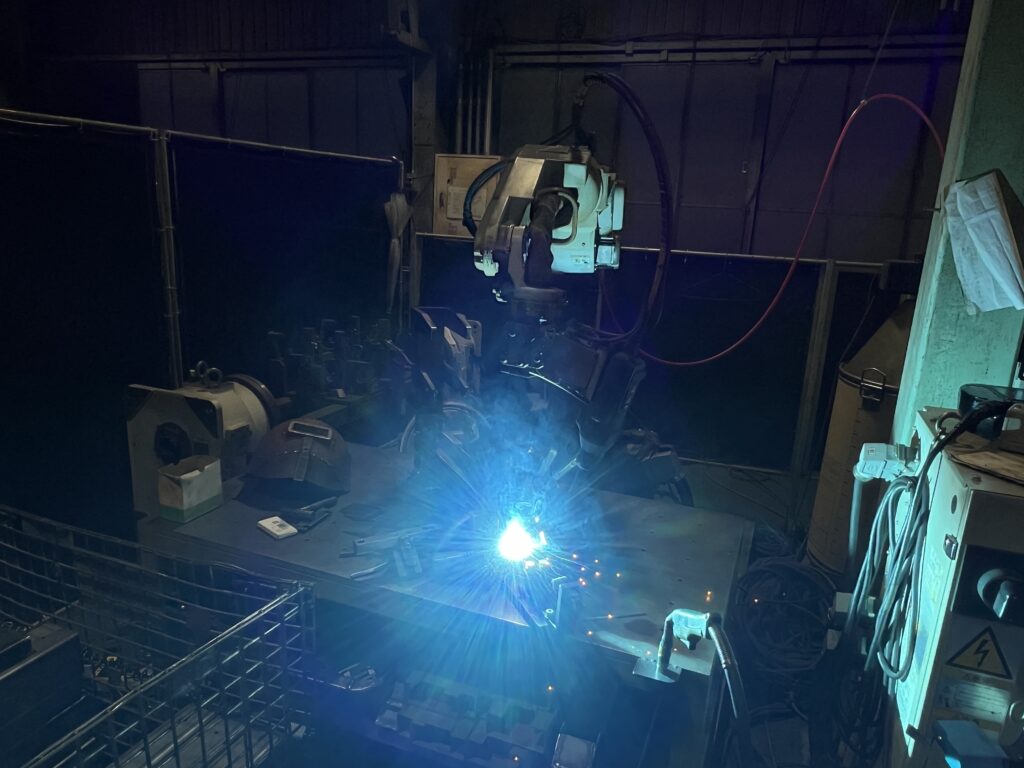

●Welding — seemingly simple, yet surprisingly profound.

Welding may look simple on the surface. However, it is precisely there that true “craftsmanship” resides.

A difference of just one degree in temperature changes the very character of the iron, and a mere 1mm shift in angle or dimension transforms the finish into something else entirely. Even in weld beads that appear identical, there are differences distinct enough to reveal exactly whose hand performed the work.

This is why we dedicate ourselves to every single line. We are not simply melting the metal, but rather…

❝As if in dialogue with the iron itself, we forge the connection with our hands, our eyes, and our every sense!❞

●Finishing and Final Inspection after Processing

Once the frames have been assembled and welded, we verify their dimensions through visual inspection and gauges. We never settle for saying “this will do” — instead, we continue to refine the work as many times as necessary until we can confidently say, “this is exactly how it should be.”

●Improvements and Safety Activities

To create even better products, we are dedicated to daily improvements. These include optimizing our jigs, reviewing workflow efficiency, and sharing insights within the team. Continuously pursuing the standard of “Safe, Fast, and Beautiful” is an essential part of our work.

Our PL & Self-Propelled Frame Unit is a team of seven craftsmen. While our ages and backgrounds differ, we are so perfectly in sync that a single glance or a few exchanged words during work is all it takes to understand one another.

We are a team where trust precedes words. The combination of “veteran expertise” and “youthful energy,” fueled by a shared passion to “always do better,” comes together to bring each product to life.

The seven of us prioritize constant communication and truly live by the motto “one for all, all for one.” Beyond just following blueprints and measurements, we share our intuition and technical expertise. We have built a system where we can immediately support each other to correct even the slightest misalignment or anything that feels “off.”

The reliable expertise of our veterans and the fresh, flexible ideas of our younger members intersect daily, resulting in superior quality and efficiency. This is a workplace where a culture of mutual support runs deep, truly embodying the principle that any individual mistake is covered by the entire team.

Thank you very much for reading to the end.

I tend to get a bit “heated” whenever the topic of welding comes up.

Does anyone else out there have something they feel that passionate about?

If you have similar experiences or something you’re equally passionate about, I would love to hear all about it!

Even in a workplace where sparks are constantly flying, we keep our minds at peace. With daily laughter and constant communication, we remain dedicated to the art of manufacturing today and every day.

Every single frame is infused with the thoughts and passion of the person who created it. Through this “CONNECT” platform, I hope to share these daily stories with you, piece by piece.

We look forward to your continued support for the Okudaya Giken Manufacturing Section 2, PL & Self-Propelled Frame Unit!

We look forward to seeing you in the next update, along with more stories from the shop floor!

Written by:

Hirokawa Tomotaka

Manufacturing Department, PL & Self-Propelled Frame Unit

Okudaya Giken Co., Ltd.